We should already be familiar with how resolution influences the quality of images on our smartphones, computers, and other devices with screens. The better the image quality, the higher the resolution. On these devices, the resolution measurement is used to determine how many pixels a display device can display at the same time. For example, a 1920 x 1080 screen has 1920 horizontal and 1080 vertical pixels.

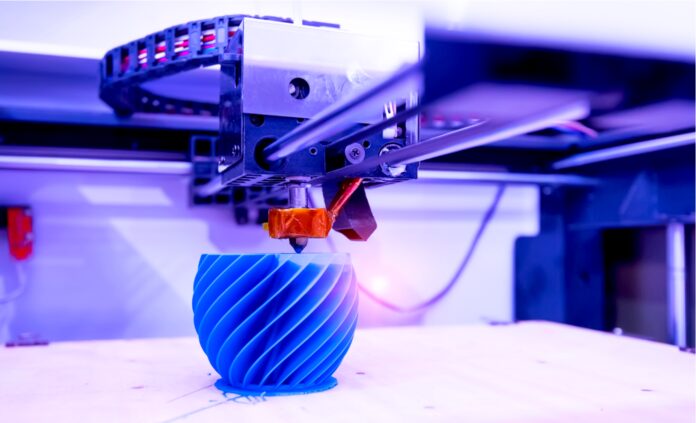

3D printers have a ‘resolution’ as well. However, since 3D printers do not use pixels, you may be wondering what resolution means in the 3D printing space. There are other 3D printing technologies; however, this article focuses on the commercially available, the FLASHFORGE 3D printer. You’ll find out more about 3D printer resolution in this article.

The 3D-printing resolution

3D printers, in contrast to the pixels in our smartphones, televisions, and other electronic devices, do not have a single resolution. Rather, there are usually two possible resolutions. In addition to having an X-Y resolution, they also have one for Z. The XY resolution represents the horizontal movement of the 3D printer, while the Z resolution shows the vertical movement of the 3D printer.

In 3D printing, the resolution is the smallest possible movement between two points, measured in microns. Therefore, printing small, highly detailed items requires a 3D printer to use its full range of resolution.

Importance of 3D printing resolution

The printer’s resolution setting will influence the 3D model’s appearance, precision, and printing time. Therefore, the resolution should be considered while creating 3D models with extremely fine details.

A 3D printer’s print quality is directly influenced by its resolution. Printed objects, just like display devices, are made up of many individual units. Pixels are the building blocks of display devices. When printing, the object is broken down into material units. A printed object’s resolution defines the overall number of material units it contains.

Low-resolution 3D printers can’t manufacture high-quality models. The printed object may have a grainy or blocky appearance. A high-resolution 3D printer, on the other hand, provides a higher level of detail. They can move around the print bed in smaller steps while making more deposits. In the end, the printed object has a higher level of detail.

In terms of 3D printing, what is the best print resolution?

At the moment, a resolution of 100 microns may be considered the best for 3D printing because it produces high-quality output with extremely accurate detailing. Moreover, it’s a resolution that many people interested in 3D printing have used, which means that it’s been tested a lot on a variety of various prints.

Nevertheless, the optimal resolution for 3D printing is typically determined by the dimensions, geometry, and level of detail of the object to be printed. When figuring out what will produce the greatest results for a particular print, it is sometimes necessary to run a few test prints. After you’ve done a lot of 3d printing projects, you should have a good sense of the minimum resolution that any object requires.

How do I make my 3D printer’s resolution higher?

On some 3D printers you can select from three different resolution solutions, each with its default speed setting. A high resolution is associated with a slow printing speed, while a low resolution has the opposite effect. For printing with PLA, there is furthermore a solution called “Hyper” available.

Maintenance of a 3D printer is important to achieving good print resolution since the moving parts of the printer can become soiled or worn down, which results in flaws in the print. Maintain an adequate amount of lubrication on all metal-on-metal moving parts. Protect your machine from dust by keeping it covered when it’s not in use.

3D Printing Time and Resolution

The time required to manufacture the print will increase proportionally with the print’s resolution. The resulting curves are smoother when setting the layer height to a lower micron value, which corresponds to a higher resolution. Print speed and resolution are interdependent. When it comes to print speed, a slower print speed will, in some ways, produce better results. However, If you move at a pace that is too sluggish, you may experience other problems, such as the nozzle becoming overheated.

Is 3D Resolution Affected by the Size of the Nozzle?

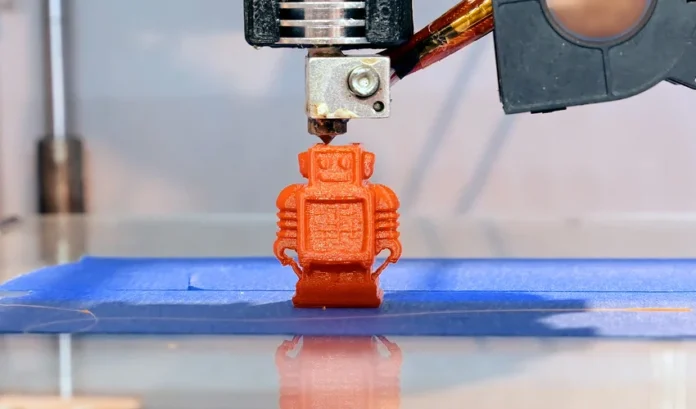

Yes, the nozzle size is comparable to the tip of a pencil; the smaller the tip, the more accurate it is. It’s relatively common these days to find 3D printers with 0.4-millimeter nozzles, which can print layers as thin as 0.1 millimeters (0.063 inches; 0.03 inches).

The print nozzle is an essential component in terms of print resolution because it is where the material is melted before being extruded. If a nozzle has a diameter of 0.4 millimeters, then 0.4 millimeters is considered the “minimum feature size.”

3D printers allow you to experiment with different projects by swapping out the nozzle for nozzles of different sizes.

When the resolution is not important

If you’re using a 3D printer, you want to get the best results possible, which means you need to think about all of your options. But a high-resolution finish isn’t always necessary. As far as part geometries, production and use are concerned, this is a matter of personal preference. When there are time constraints and less demand to print in high resolution, less care or worry can be taken with the result. On the other hand, a higher resolution is great when there is a requirement to print in high quality. Cost can also be a factor, especially if costs need to be kept as low as possible. It costs more to print at a high resolution. However, low-resolution objects can be made without any worries about the cost.