Industrial hardware is essential for many industries and projects. From construction sites to manufacturing plants, industrial hardware plays a vital role in helping these businesses achieve success. With components like screws, bolts, nuts, and other fasteners, industrial hardware can enable businesses to make sure that they have a reliable assembly that will stay secure and durable.

Beyond just fasteners, industrial hardware also encompasses other pieces like clamps, shackles, and other pieces that can make sure that everything is securely held in place. Industrial hardware is essential for any project that requires precision, reliability, and durability all of which are key components of a successful operation. The best industrial hardware products on the market are here, https://my.rs-online.com/web/c/engineering-materials-industrial-hardware/.

Modern industry relies heavily on the use of high-performance industrial hardware to keep operations running smoothly. From warehouses to manufacturing plants, the hardware used to power the machines and systems that keep business going must be durable, reliable, and of the highest performance. Here are some types of industrial hardware that can help keep your industrial operations running at peak efficiency:

-

Motors

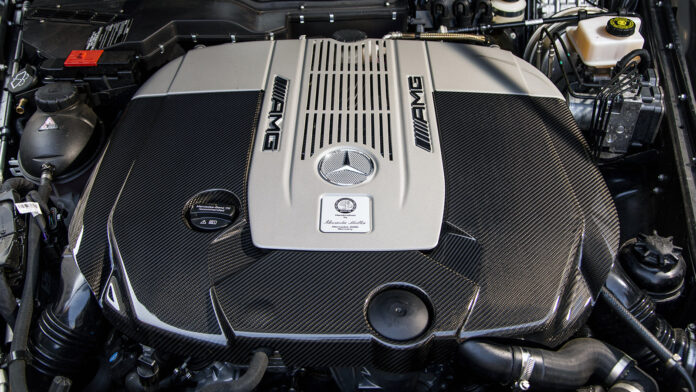

Motors are the powerhouse of industrial hardware and are an important component in any high-performance setup. They provide the motive force needed to make any industrial process run smoothly, from powering automated production lines to providing the torque needed to operate heavy machinery. Motors come in a variety of sizes and styles, ranging from lightweight and energy-efficient DC motors to high-powered AC motors with higher torque output.

When looking to enhance the performance of your industrial setup, consider the offerings of Southwest Performance Parts. Their range of high-quality motors and components can provide increased power, efficiency, and reliability for your specific application. Whether you need a motor with improved speed, precision, or overall performance, Southwest Performance Parts has the solutions to meet your industrial needs.

-

Actuators

Actuators are an essential part of any industrial hardware setup, providing the mechanical force necessary to make various processes run smoothly. They come in a variety of shapes and sizes, from linear actuators to rotary actuators, and can be used to move various components in a given industrial application.

-

Sensors

Sensors are a crucial component in industrial hardware, as they provide the data that allows machines to function properly. They help machines detect their environment and respond to changes, and come in a variety of types, such as proximity, motion, optical, temperature, and humidity sensors. High-performance sensors are designed to provide accurate, reliable data and robust connections, making them an invaluable part of any industrial system.

-

Pumps

Industrial settings require reliable and high-performance hardware to ensure their operations run smoothly. Pumps are essential in industrial settings and come in a variety of sizes, designs, and materials. They are used to move fluids and gases, including water, air, oil, and chemicals. Depending on the purpose, pumps can be single-stage or multi-stage and can be powered by electricity, gasoline, or diesel.

-

Valves

Valves are an essential component of industrial systems, used to regulate the flow of liquids and gases. They come in a variety of shapes, sizes, and materials depending on the job. Common materials used in valves include brass, steel, plastic, and cast iron.

-

Controllers

They’re designed to provide an efficient and reliable way to control a variety of functions, like machines, processes, and other equipment. With the right controller, you can make sure that operations run smoothly and that any glitches or issues are quickly identified and resolved before they cause any downtime. They’re also great for monitoring performance and making sure everything is running as it should be.

Benefits of High-Performance Industrial Hardware

High-performance industrial hardware can be of great benefit to factories, allowing operators to work more efficiently and reliably. With a wide range of hardware available on the market today, it is important for operators to make the best choice for their facility needs. Some of the main advantages of high-performance industrial hardware include:

- Increased Productivity: High-performance industrial hardware can help factories increase their productivity. By offering superior speed and performance related to AI and machine learning, these systems can help improve overall operation efficiency in a variety of ways.

- Cost Savings: High-performance systems are typically more expensive than standard hardware solutions, but they often provide significant long-term cost savings by eliminating the need to constantly upgrade or maintain inefficient components.

- Improved Technician Support: Many manufacturers provide reliable support technicians who understand the specific features and capabilities of their software and can quickly diagnose potential issues when they arise.

- Enhanced Safety: Highly reliable industrial systems are great solutions for safety critical operations, as they reduce the likelihood of malfunctions or errors in processes that could lead to injury or death. They also enable automated processes that eliminate some manual labor tasks that could be hazardous when improperly performed.

Factors to Consider

When choosing industrial hardware, there are many factors to consider. The first step is to determine what type of environment the hardware will be operating in. Depending on the setting, certain materials and components may be more suitable than others. For example, in a dusty or wet environment, plastic may not be a viable option and more corrosion-resistant metals may be better suited to withstand the elements.

The important features of the hardware should also be carefully evaluated. The requirements for power input and output should match the specific application needs and all safety features must meet specific specifications for those working with it or around it. Additionally, systems must work together harmoniously and have clear communication protocols so all parts of the operation can interact efficiently.

From a commercial perspective, longevity is key as any repairs or replacements can eat away at profits. Proven reliability from known manufacturers is always a safe investment – comparing customer reviews and market performance across different brands can help make your decision easier.

Lastly, decisions about maintenance plans and warranties should not be taken lightly as some of these will depend on your budget constraints; however investing properly in high-performance industrial hardware can provide major advantages in terms of production turnaround time and cost savings over the long run, leading to a more efficient factory overall.

Conclusion

From basic add-ons to comprehensive solutions, companies can find just the product they need for their specific industry needs at competitive prices. Investing in high-performance industrial hardware will ultimately pay dividends for any organization wishing to succeed in today’s competitive manufacturing environment.