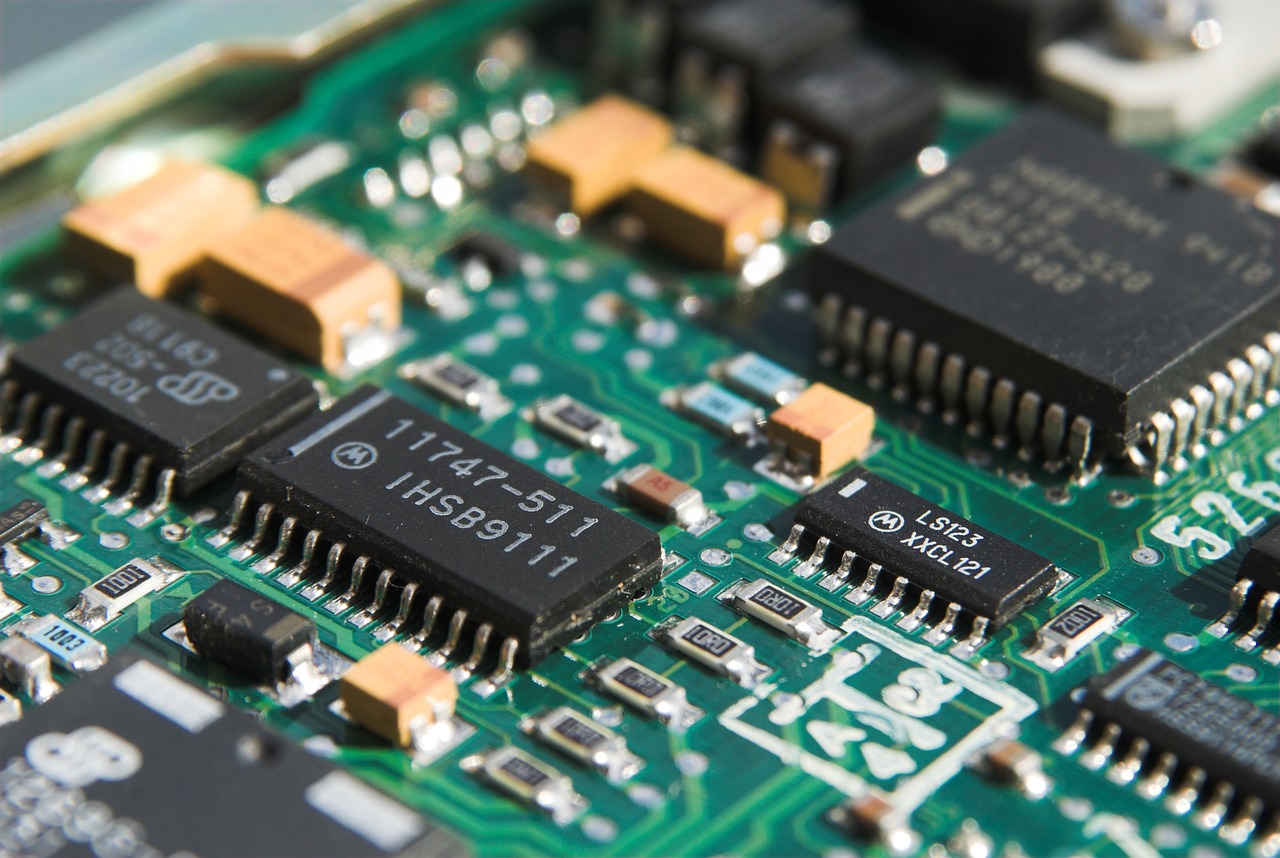

The printed circuit boards are some of the most used items in today’s world. They are the reason why we can use our electrical devices, and their components allow communication between different functions in one device. Millions of these units are produced every year, and their durability and function depend on the materials that are used. Starting from the temperature they can withstand, up to strength, resistance, and overall durability, the way they are made will affect all of these things and much more.

If you are in this industry, you probably already know that there are a lot of different designs you can create, and depending on the idea you have, you need to choose the best components for your units. In this article, we are going to give you some tips for choosing the right PCB material for your needs. Continue reading if you want to find out which materials affect the rigidness, what you need to use to make the units flexible, along much more.

1. Thermal characteristics

The first thing you should consider when picking the right elements for your board is the properties that come with the materials. You should think about the thermal properties along with the electrical ones.

When it comes to the thermal ones, they are closely related to the product’s ability to conduct electricity. Know that when you are closing the right element for your needs, you should always look at the numbers and see the heat capacity along with the stress, expansion, and thermal conductivity.

Check the vitrification temperature or Tg on every material you are considering and know that when it comes to units that are high performance, they are going to have a vitrification temperature that is higher than 170 degrees Celsius.

Know that FR-4 has the lowest Tg, 135 degrees Celsius, whereas, polyimide has the highest, or 250 degrees Celsius or more.

2. Electrical characteristics

Another property that you should consider is the electrical one. The reason why you need to think about this is that it is going to affect the whole product, especially in the use. Know that in today’s market, we are all expecting to have units that are going to provide high electrical performance, along with a low cost. You should be looking at the dialectic constant, or dk when checking the properties that the material offers.

Know that this number is usually between 2.5 and 4.5, however, it will decrease when it comes to higher frequencies. The PFTE has the lowest dialectic constant, 2,1, whereas, FR-4 High Tg has the highest and that number can go as high as 5.4.

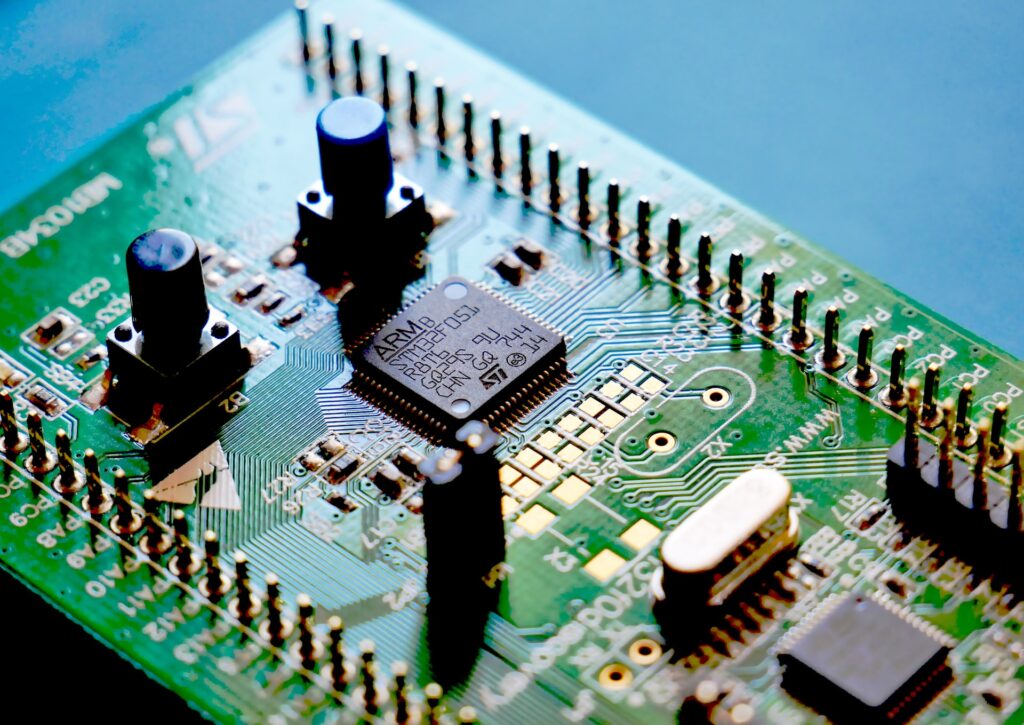

3. Quality

The next thing you should think about is the quality of the elements that you are going to use in the production process. The quality does not depend on just one thing, and you need to look at the overall properties, along with the cost, the pros, and the cons of using the material. You should also consider the applications because where you are going to put the unit is as important as the properties it comes with.

Know that when choosing the right elements, you should also look at the documents, along with the requirements it comes with. According to PCBOnline, you should be looking for systems that provide a wide range of performance versatility, along with ease of processing.

4. Cost

Now let’s talk about probably the most important things when it comes to the production process and manufacturing – the costs of the materials. No one wants to spend too much money on the elements, but you should know that sometimes, you need to pay a little bit extra for the right products.

You should know that most of the manufacturers use solder tabs or gold ones, and they are the most popular because they are cost-effective and they are durable. Once again, you need to consider the properties of the elements, and depending on that, choose the right one for your needs.

The ones that are going to be able to withstand higher temperatures, are more versatile, and are durable will come with a higher cost than others. Note that the spacing will make a difference in the cost as well, as the units that come with spacing above 6 mils will come at a higher price.

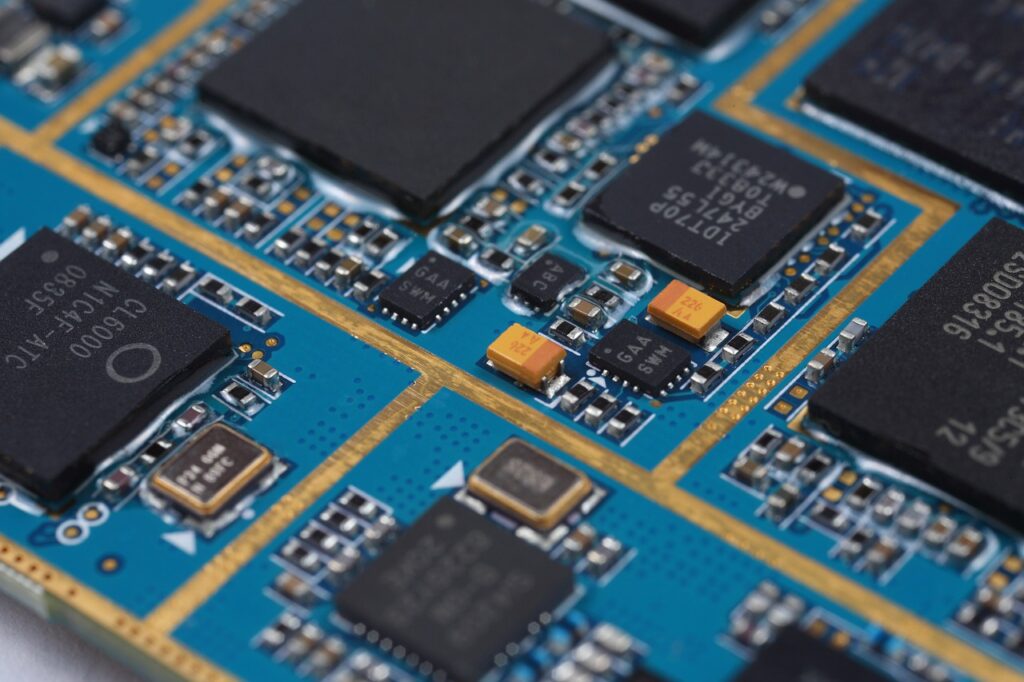

5. Pros and cons of the most commonly used materials

The last thing we are going to talk about is the characteristics of the most popular materials that are used nowadays, and where you should use them.

Aluminum base is mostly used in products that need to withstand high temperatures, like LEDs, and they are said to be the best when it comes to heat dispersion. This element comes at a low cost, it is really durable, and it is probably the most environmentally friendly matter that you can find.

The flexible materials allow the product to be elastic, which makes it less likely to get damaged with usage. Note that these elements usually come with a higher price, but it is said that it is worth it. They are less likely to get damaged because they have fewer components that could break. They are also the smallest, and because of this, they are used in devices that have capacity limitations.

Lastly, we have FR-4, and this element is preferred when it comes to creating rigid units that can be layered. They have low water absorption which makes them more durable, they have great insulation characteristics, and they are the most popular with manufacturers. In addition to all this, there are a lot of different FR-4 materials, and you can easily choose the right one for you depending on your needs and their characteristics.

These are some of the things you should consider before choosing the right material for your PCB. Know that you can always consult with a professional depending on the products that you want to build. Closely inspect all the characteristics and learn what every number means. The elements you choose will not only affect the properties of the unit that you are going to build, but they will also represent your company and skills with your users, so take your time, and consider all options before settling for the best one.