There are plenty of differences between absolute and incremental encoders. Those working in consumer electronics or the automation industry will tell you that these components are vital for the overall successful working of machinery, gadgets, etc.

But what exactly are these differences? To explain that, we will have to go through both absolute and incremental encoders and learn what exactly are they.

So with all that said, let’s start.

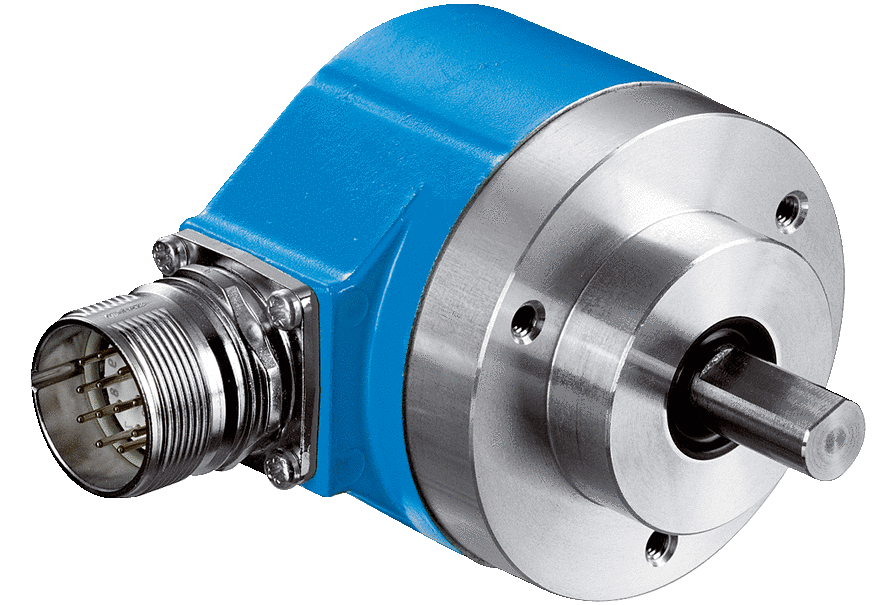

Absolute Encoders

The first component on our list is the absolute encoder. What makes this component important is the fact that it knows its position with the shaft regardless of the component is powdered or not.

Both absolute and incremental encoders are placed next to a shaft and use to measure the angle position. One of the first differences between both is the use of single or multiple turns, which ultimately calculate how many turns the shaft has made in total.

Naturally, both single and multiple turn absolute encoders can be used for various things. In the case of single-turn encoders, they’re best used in machines, gadgets, and applications that don’t require lengthy traveling and measuring of position.

Multiple turn encoders are used for far more complex measuring. Another difference between absolute and incremental encoders is the advantages that each one has. In the case of the former, there are a couple of notable advantages that you should be aware of if planning on using them.

The advantages to using absolute encoders are:

- We always know the position even if nothing is powdering the application

- We always have access to information as the encoder will always read even if the position is not required

- Uses advanced technology that doesn’t require battery backup

- Doesn’t need an optical disk, which is the traditional component of encoders

- Up to 44-bit multi-turn

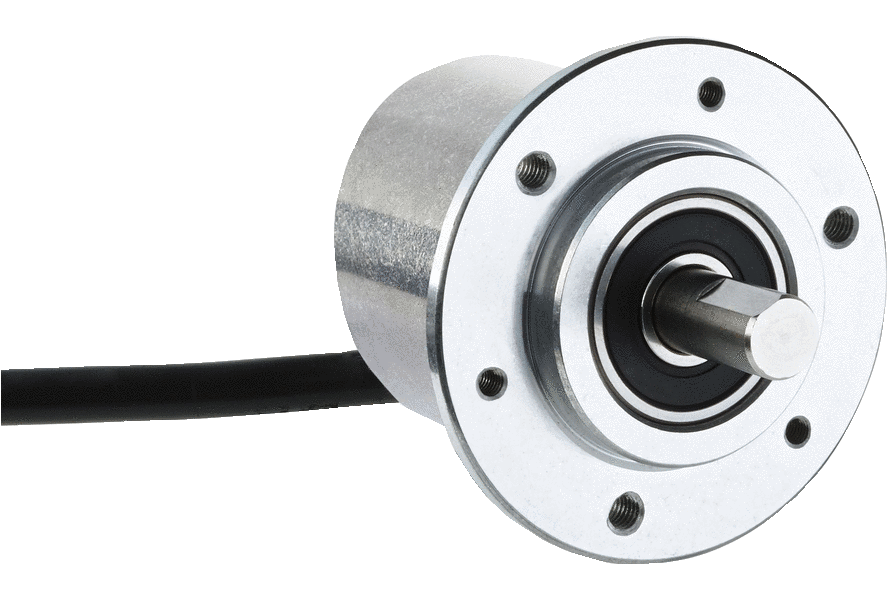

Incremental Encoders

Encoders fall into many subcategories, and incremental types are no different. Much like their absolute counterparts, incremental encoders use magnetic, optical, inductive, capacitive, and laser technologies to power it up.

At the base of it, incremental encoders are electro-mechanical, meaning it uses the shaft to translate its position into digital or pulse signal. It does this through a traditional optical disk, although other methods are also quite common. When an incremental encoder operates, it will count the number of pulses and give you certain feedback.

A huge difference between incremental and absolute encoders is the fact that the former doesn’t store the position once powered down. If you power down and power up an incremental encoder, it will reset and start counting from zero. This is probably the most notable and biggest difference between both types.

Same as their absolute counterpart, incremental encoders do have their strengths. These include the following:

- Generally costs less to buy and run

- Less complex due to the fact that it doesn’t have a multi-turn sub-type

- Cannot be hindered by loud noises

If you’re on the market for incremental encoders, then make sure to visit Encoder.com to get stocked.

Differences Between Both

Now that we’ve explained both types, let’s dive deeper into the main differences between both types. Although we did touch on some of the differences in the previous points, we will try and explain all the major differences that both types share. So let’s go ahead and do that.

1. Operating Principle

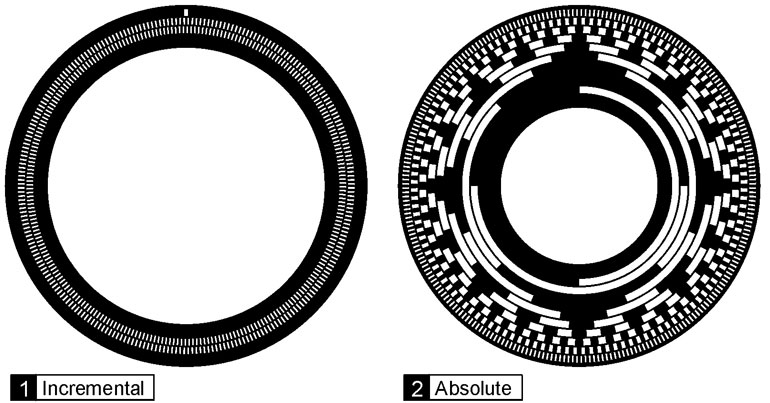

The very first difference between both types is the fact that they operate on a different principle. For absolute encoders, they operate on a binary sequence. An incremental encoder operates by counting pulses on a reference point.

2. Cost Efficiency

The second difference is how cost-effective both types are. Experts in the industry will tell you all about the complex design of these devices, and will also tell you that absolute encoders can sometimes cost twice as much as incremental ones.

3. Stability

Since incremental encoders won’t count if the device is powered off, it makes the job much more difficult. Readings can be missed in the case of power shortages and that can mess up entire calculations.

That isn’t the case with absolute encoders as they can read and count even if there is no power. This gives you overall better performances, more accurate results, and of course, higher measuring stability. In short, absolute encoders will not lose position information under such circumstances and that makes them more stable.

Sensing Technology

Since plenty of technologies are used in the making of encoders, we can safely divide them into magnetic, optical, inductive, capacitive, resistive, and mechanical.

This is yet another difference, but one that has to do with the method of coding each position. Based on all that, we can also determine the sensing technology. Let’s explain these sub-types.

· Magnetic

This technology is pretty basic and commonly used with encoders. Magnetic technology uses the magnetic poles to produce results, sending sensor readings through both poles.

· Optical

Optical technology is the most common with encoders. It works by sending an optical signal through a disc. The disc in question is generally round and has holes through it. The signal is received by a receiver that fixes it.

· Inductive

For inductive technology, we need to place an electrically or ferromagnetic metal at a certain point between the sensor and the encoder in order to measure.

· Capacitive

Capacitive encoder technology operates on the principle of rotating. Whenever the sensor rotor rotates, it transmits a signal which is then tracked by a sensor. The sensor sends the signal to a receiver board, where it can be translated into a signal.

· Resistive

Resistive technology is widely used as it essentially translated the signal into digital or analog. Resistive technology uses a number of processes to achieve the desired signal.

· Mechanical

Mechanical technology uses electrical sensors to generate signals. It does this through metal discs and sliding contracts for measurements.

Conclusion

There are plenty of differences between absolute and incremental encoders. Not only do they vary in operating principle, but they also vary in cost-effectiveness and much more.