More and more people are worried about the environment, so they do everything in their power to decrease pollution and protect our planet. Yes, there is still a lot that has to be done, but one has to begin somewhere, right? Taking this into consideration, it comes as no surprise that many industries and improving their equipment and changing the way they conduct their work to reach this goal.

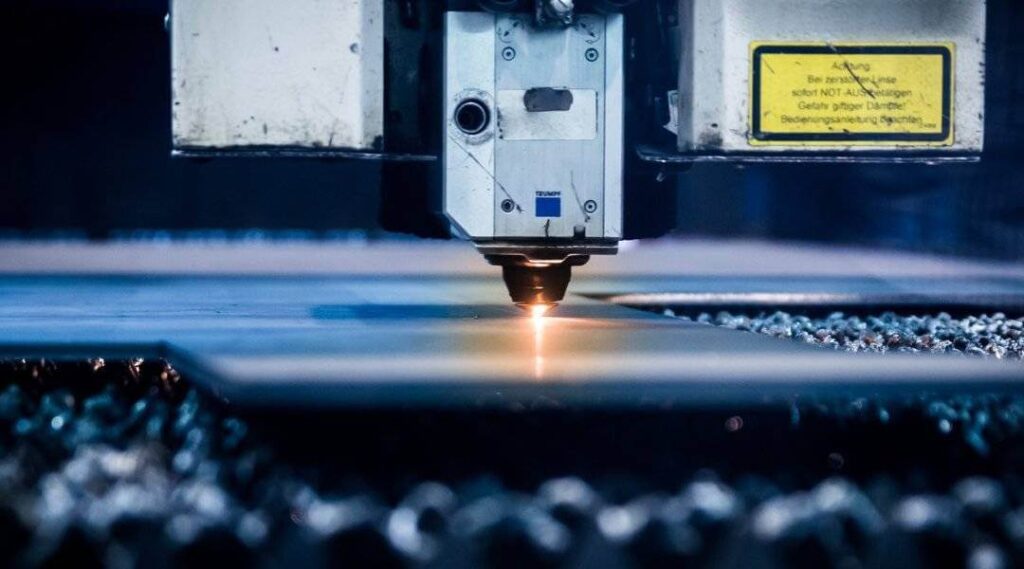

The laser marking industry is no different, so we will focus on these machines in the following article. We will answer the question of how eco-friendly they are and also tell you more about the application of this equipment.

What are the benefits?

Not a lot of people make a direct connection between laser technology and a decreased ecological footprint. Nevertheless, there are many ecological benefits of this technology, and here are some of them.

It reduces waste

As you probably know, the traditional techniques of engraving items with barcodes, seals, logos, and safety information include the use of harmful substances. However, this is not the case when it comes to laser technology. When using this technique, manufacturers eliminate the need for any additional substances since the laser cuts directly through any type of material. No, there is no need to use ink or any other additional methods. There is no need to point out how beneficial this technology is for recycling.

In addition, the technology also significantly increases the safety of the products. How? Well, as already mentioned, it completely eliminates the need to use ink, which is harmful to consumers, so they have to be very careful handling the items. The use of laser technology is especially beneficial in the food and medicine industries since there is no danger to the consumers.

While on the subject of waste, we also have to remind you that during traditional techniques of engraving, a lot of waste material is generated. Well, this is not the case with the laser method since it melts the parts of the item that then vaporize, and therefore, disappear.

It uses less energy

Yes, we can all make our contribution to protecting our environment by using less energy, but the truth is that we alone cannot make much of a difference. Large industries have an important role to play also, and this is when laser engraving comes in.

Due to the fact that this technology significantly simplifies the whole production process, it means that less energy is utilized during it. We have already mentioned that there is no need to use additional methods and substances, so manufacturers are nowadays enabled to create products of the highest quality while at the same time lowering the consumption of energy. Is it really necessary to explain how beneficial this is for our environment?

It decreases production costs

We have already mentioned that this technology uses less unnecessary energy, but that is not all. Taking into consideration the entire manufacturing process and the fact that other techniques and additional materials aren’t necessary, it is quite obvious how much money this technology saves. When using laser engraving, manufacturers don’t have to purchase ink, lubricants, and other substances. In addition, they also save a lot of money on materials since this technology works beautifully on raw ones.

Finally, oftentimes, they don’t have to use additional pieces of equipment, which means that they don’t even have to buy it. The biggest advantage of the laser method is that it is extremely precise, meaning that they can use only this machine to create even the most intricate designs. As you can assume, this is especially important in jewelry production since the pieces are quite small. If we are being honest, jewelry laser engraving machines are one of the most popular tools, and you can learn more about their feature on this website. Basically, they enable an individual to start their own business, and the only investment they have to make is to purchase one of these.

Long-lasting machines

This benefit isn’t only important for the environment but also for the manufacturers. Let us explain. When it comes to the former, you have to remember that these machines can last up to 15 years or around 30,000 hours. What’s more, they are really easy to maintain, and malfunctions rarely occur. It means that it won’t be necessary to complete expensive repairs and change certain parts of the machine often. Obviously, this is a feature that significantly lowers the amount of waste because where do the broken parts go? This is the most common issue industries face nowadays, so they do everything they can to boost their production process and to use state-of-the-art equipment. Their main goal is to minimize the risk of malfunctions, and therefore, save money on repairs, but also to reduce waste.

On the other hand, when it comes to the latter, this feature is pretty clear. When starting a business, you have to use tools that will enable you to create products of high quality, but you also want those tools to last for as long as possible. Well, we would say that 15 years is quite a life span, wouldn’t you?

What are the applications of laser cutting machines?

Before we conclude this article, let us give you some examples of products that are created with this technology. First of all, there is jewelry, which we have already mentioned. Since these machines are available for anyone to purchase, you can easily start your own jewelry business. Similarly, you can also create any kind of personalized merchandise. People really like these and are ready to pay big bucks for them. Remember that the main feature of this machine is its precision, which means that you can create any design that comes to your mind.

Also, this technology is used in the automotive industry and medicine since each item must have specific details engraved on them. Depending on the industry, it may be a simple serial number, or it may include additional safety instructions. Nevertheless, the bottom line is that laser engraving is being used across multiple industries, and as you can see, it is pretty eco-friendly.